Alright, $24 for a melamine top, $28 for a register cover, $85 (ouch!) for new hinges, and I used drawer pulls, scrap wood, stain and polyurethane that I already had, and this cabinet lives another day. Oh, and I needed to order some special cabinet screws for those drawer pulls, so another $8. (I had existing screws but the heads kept popping off; I have a real low tolerance for that.)

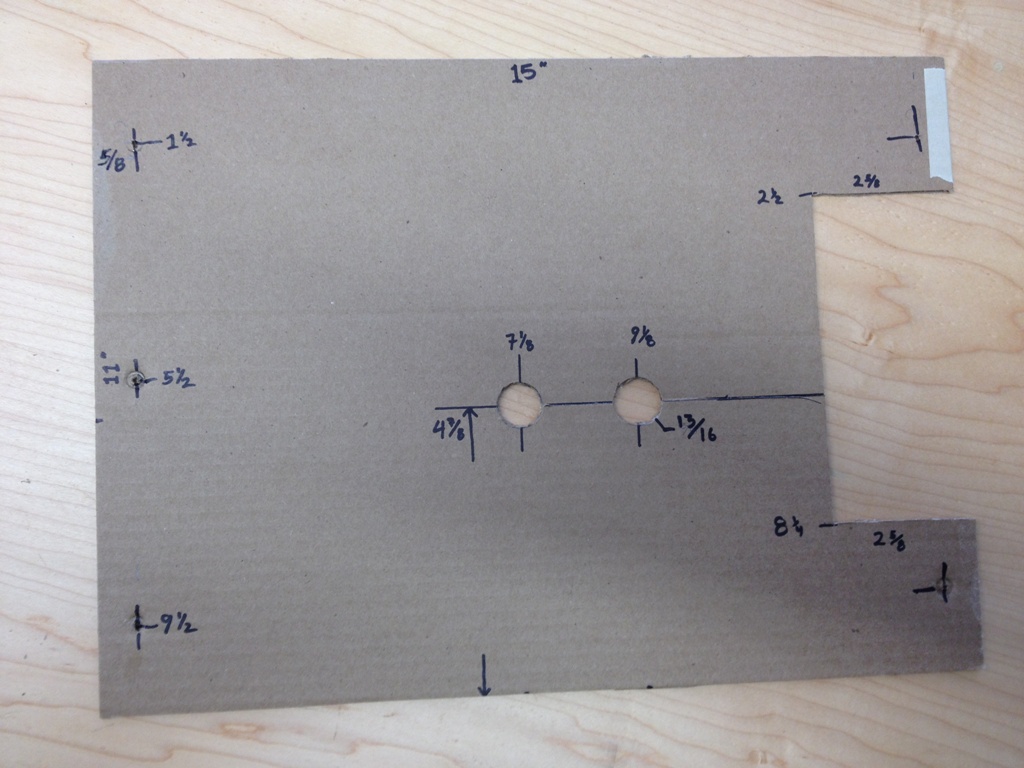

Here’s a little trick for when the holes for your new hinges don’t line up with the old holes. Now, you’re going to drill new holes in new locations and that’s fine. But this is such a small area that if you leave the existing holes alone, the wood gets really weakened. So you want to stuff something into that hole, a little dowel or even a couple toothpicks and wood glue will seal it up fine. Maybe it’s overkill, but it does prevent the new screw from trying to wander into the old hole, making your hinge install go wonky.

One challenge I faced is that the door frames were all skewed. I think when this cabinet was moved, the whole thing kind of slanted over, making distinct parallelograms where you really want rectangles. Oh well, huh? So no matter how I cut and trim and shim the cabinet doors, they’re not going to close straight.

BUT THEY DO SHUT! And they shut cleanly, That alone is an improvement.

Nonetheless, it’s still the Cabinet From Hell. It’s just less of an eyesore now, and it will serve and function until such time as I decide to make a new cabinet for the laundry room. A task that I can now put off another few years while I work on fixing other broken things around here.

The melamine top is the biggest difference by far. You can clean it. You can spray it with windex and it actually comes clean. Amazing.

Our laundry room is a hard working room. A lot gets done in that small space; not only laundry but storage, cat dining area, and the only place in the house that the microwave will fit. And now it’s just a little less embarrassing. New flooring too, but I’m holding off on pics until that’s finished.

If I owned a cat restaurant, that’s the pic I would put on the wall.