One thing I’ve always wanted to do with my table saw is really seal up the interior so sawdust doesn’t get all over the place. In my former shop, I used to have it boxed in and connected to a vacuum hose, but that was really ineffective and I kept tripping over the hose. So now I basically have the housing all sealed up and I put a bucket underneath it. It actually works really well, except that I never did seal up the backside. That’s where the motor and the pulley pokes through making it difficult to really seal up.

Well, I finally got around to making a back plate that should cut down on the sawdust considerably and not interfere with the motor and pulley. I was going to go with sheet metal but I didn’t want anything that could damage any moving parts. I needed something soft, yet firm. And cheap and easily accessible. I ended up going with cardboard.

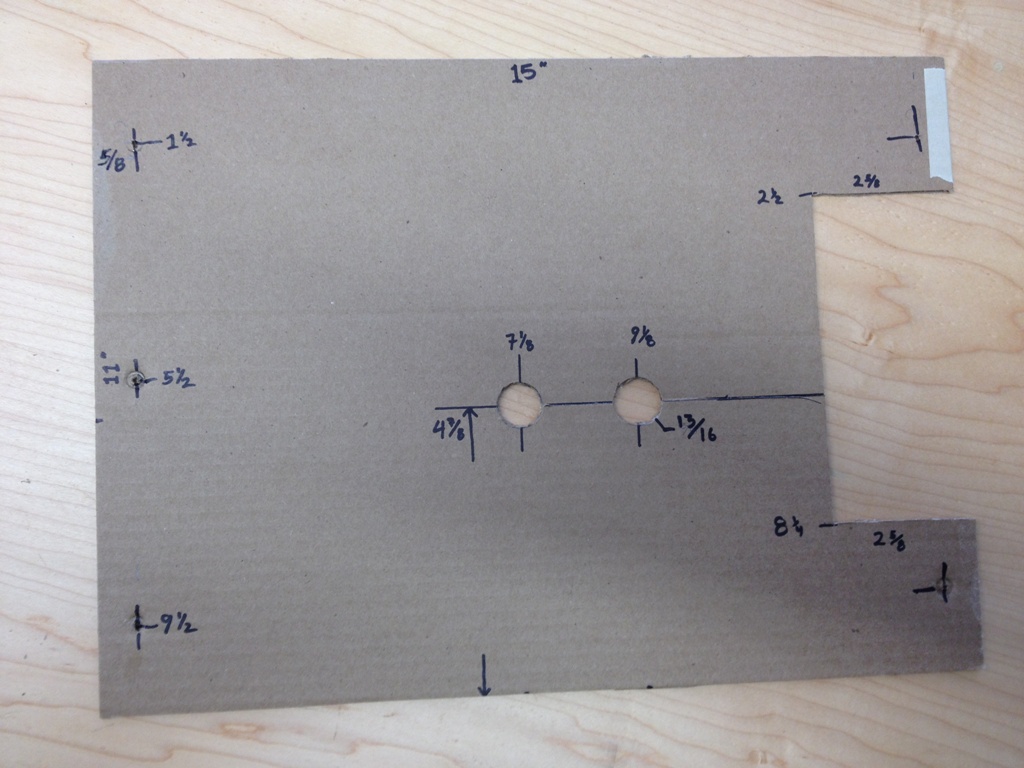

I marked everything really carefully so if I have to remake it (out of a different material if I so desire) it will be easy to do. Cardboard is soft enough that it won’t damage anything should something go wrong, and firm enough to hold its shape.

There you can see it’s a tricky fit. The holes are for the rods that hold the motor, and that slot on the right is where the pulley goes. Everything is looking great, but I do wish I had something I could use to make it a little stronger, to help it withstand the rigors of a shop.

Hmm. I wonder what I can use?

Hmm…

Oh, I know! Duck tape!

Handyman’s secret weapon!! Oh yeah, now that thing is pretty much waterproof. I’ll probably never have to replace it. It might last longer than my table saw.

I am happy to report that I can now rip down a 2×4 and not cover my entire shop floor with a spray of fine yellow powder. This contraption cut down on the dust piles by at least 75%. Yeah, I still get some. That’s okay. Wouldn’t be a shop without sawdust all over everything.