I love a finished project. Now the door is stained and has a couple coats of spar urethane on it and I even put a little brass handle on it so we can open and close it. It’s everything one would want in a screen door. The only thing it lacks is hinges, I had to order them and they have not yet arrived. But other than that, it rests in the frame and is held in place by magnetic catches and as far as I’m concerned it’s done.

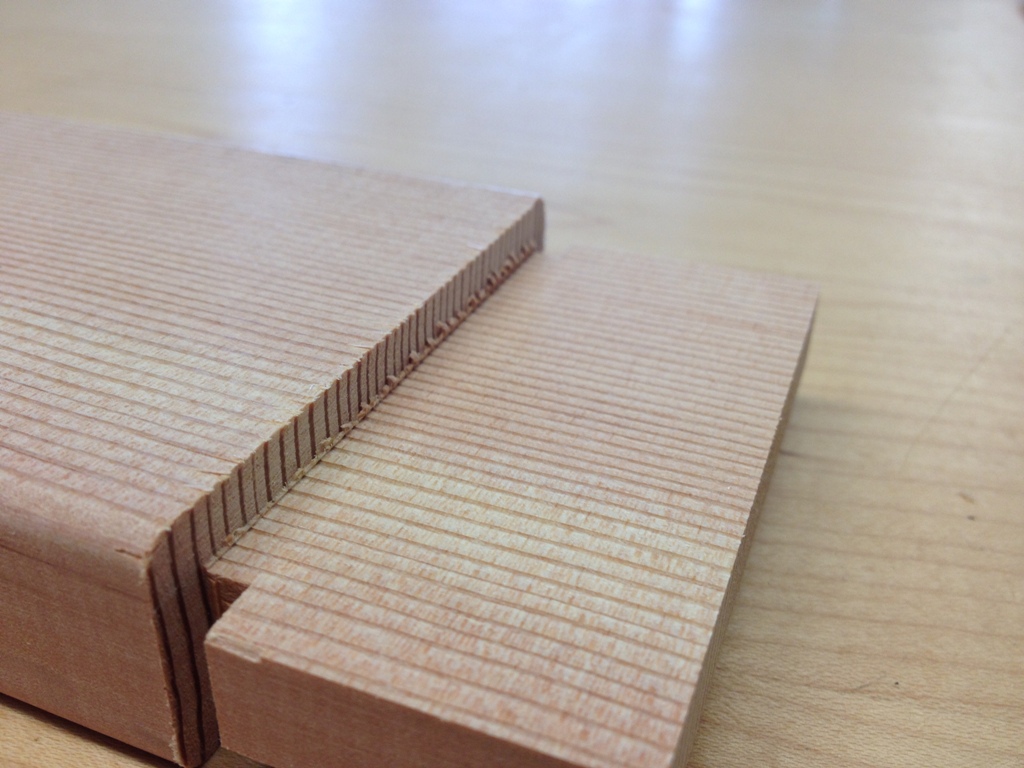

Screen technology has come a long way. It used to be a big pain in the ass when you needed to make a screen, often involving special tools and working with aluminum frames and steel mesh that all had jagged pointy ends to cut yourself on. Well nowadays, it’s still a big pain in the ass. But at least the screen fabric isn’t steel anymore, I think it’s nylon. The old steel sheets were awful to work with.

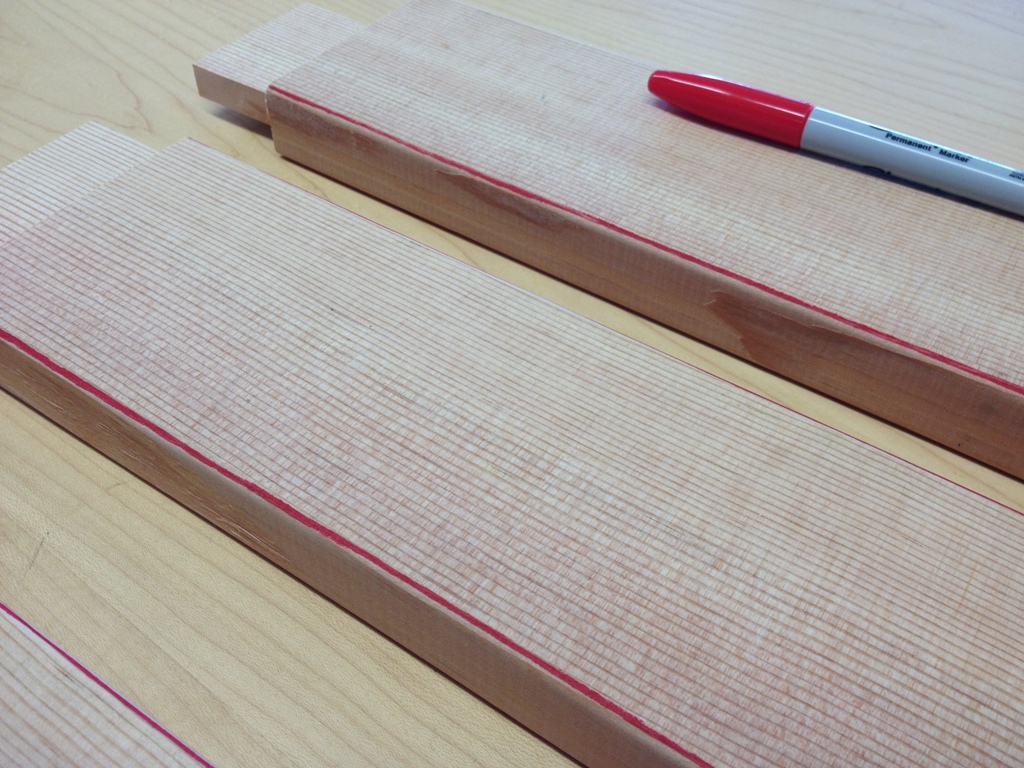

I got the screens in the frames and affixed them to the door with brass washers and screws. The brass washers came super shiny and bright, but here’s a trick. Put them on a metal wire and hang them over the flames in your barbecue grill. Let them cook for a while, get them as hot as you can. These cooked to about 700 degrees, and at that temperature the brass takes on a nice antiquated patina. (I actually didn’t want to use washers, they sell special brackets that hold these things in place, usually used for mirrors or glass panes in cabinet doors. But good luck finding those on an island.)

Here’s the finished door. I’m glad to have some room to move around in my shop, makes projects like this a lot easier.

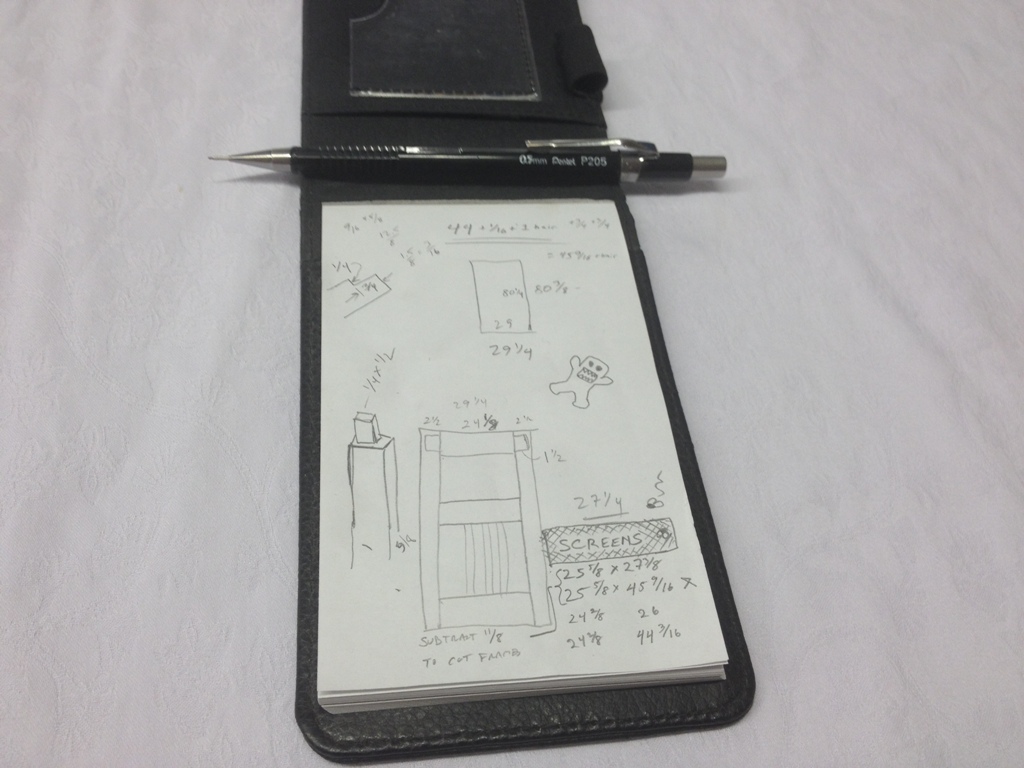

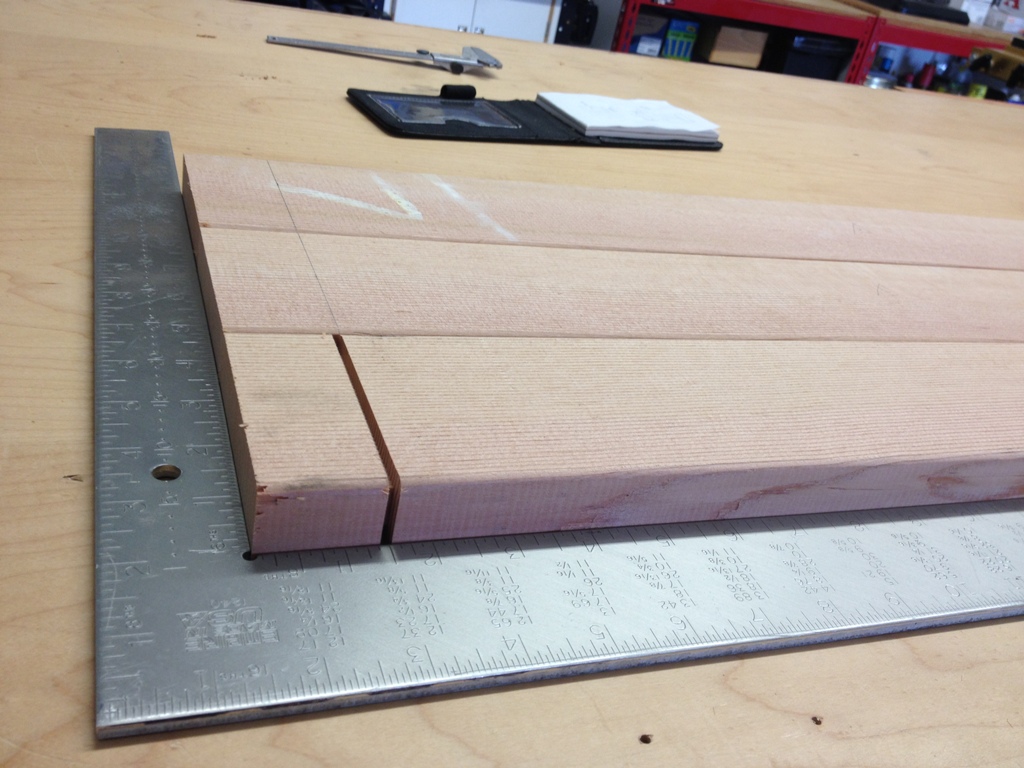

These are the full extent of the drawings I used to make the door. On some projects I draw everything from every angle but on this one I just kind of winged it. Didn’t even need to do much math.