Ah, springtime on Orcas Island. Time to get out the kayaks, the paddle boards, the canoes, the sailboats, that pontoon you made out of empty 2 liter soda bottles. Whatever floats your boat, literally. Time to get out in the water and go fishing, go sailing, go floating around the island and seeing all the wildlife. The weather is beautiful, warm but not hot, sunny and sometimes a little cloudy. The wildlife is abundant. Time to go out and just enjoy the world.

UNLESS YOU’RE ME.

If you’re ME, you spend every waking moment in your troll cave, making sawdust with your saws, rasps and sanders. You avoid bees as you run up to the shed to get more lumber. You spook a bunch of deer as you head back to the other shed where you store all the paint supplies. You pay no heed to the tourists driving in their strangely clean cars, completely devoid of mud, rust and dents, staring at you as if you’re a Bigfoot sighting. If you’re ME, you toil in your shop, listening to playoff hockey or reggae music or whatever your little device will pick up without dropping its signal.

My deck becomes Stain Central, where I can set up sawhorses and drop cloths, and slather linseed oil onto all those little shapes that I made in the shop. They’re like big puzzle pieces at this stage. One thing I really enjoy up here is the space, the almost limitless amount of places I can spread out into. I don’t have to cram this into my shop and stink it up with oily fumes for 48 hours. I can do this on the outside deck, and gaze out to the sea when I take breaks.

My deck becomes Stain Central, where I can set up sawhorses and drop cloths, and slather linseed oil onto all those little shapes that I made in the shop. They’re like big puzzle pieces at this stage. One thing I really enjoy up here is the space, the almost limitless amount of places I can spread out into. I don’t have to cram this into my shop and stink it up with oily fumes for 48 hours. I can do this on the outside deck, and gaze out to the sea when I take breaks.

This install was really tricky. I had to hold the bracket in place with one hand and the 2×4 in place with the other hand while driving the screws in with my third hand and making sure everything remained level with my fourth hand. The worst of it was one of the beams ran along the exact same path as the electrical wires behind that drywall. I had to screw it into the studs without screwing into a live 220 volt wire. Call me a chicken, but I actually wore rubber gloves when I drove those screws in. Well, they’re all in, and those brackets now hold up a little side bench that is about as sturdy as bedrock. The best part is the top is just a sheet of 4×8 plywood ripped down into two 2×8 sheets and screwn together. So I can pound on it, drill through it, spill crap on it, and for $32 I can replace it and it will look like new. To me, that’s a really good quality to have in a bench surface.

So there’s the side bench. It’s just a little lower than the big bench, and it’s made to be the exact same height as my Festool radial arm saw surface, so if I have long strips of lumber or trim to cut, I can rest it on this side bench when I’m cutting it.

I also took some time to rearrange a few tools on that pegboard back there. You know, I have this obsessive-compulsive disorder, and I’ve learned that I shouldn’t resist it. I just run with it. When my brain tells me my tools need to be in a certain order, I just make it happen. No point even trying to prevent it.

The shop is almost done and I’m going to post a bunch of pics and a nice little tour of it soon. Then it’s back to working on the house, which is nowhere near to being almost done but we’re happy with every improvement we make. Soon I’ll be making cabinets, and furniture, and doing finish carpentry just the way I like to be doing.

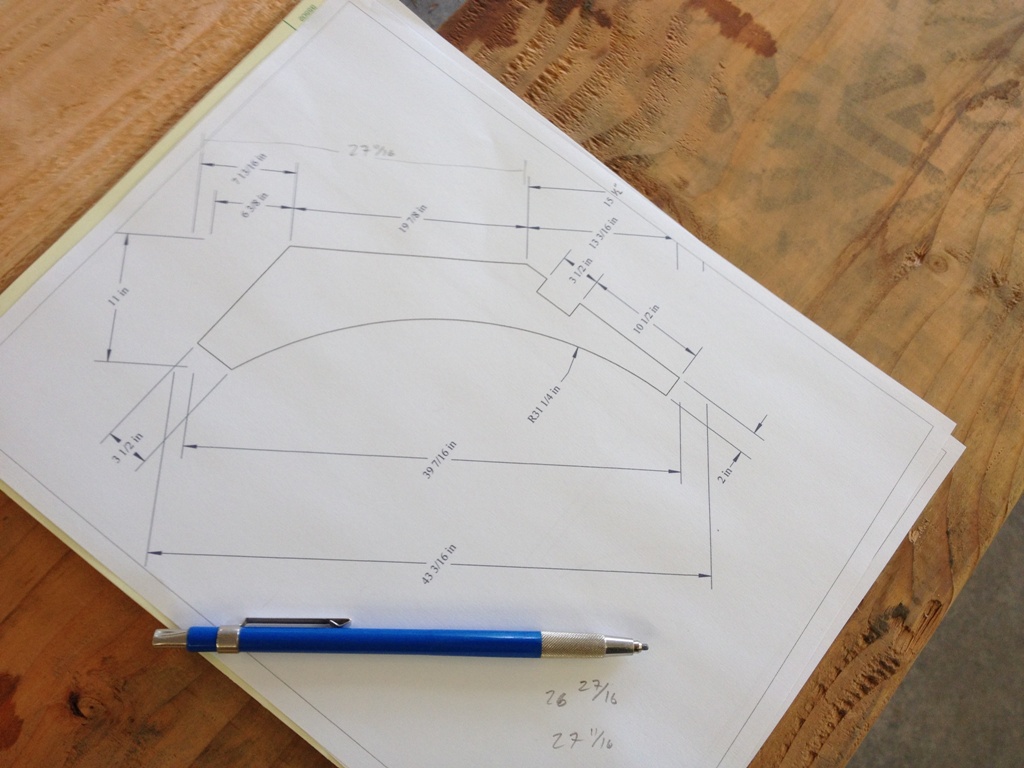

Maybe I’ll buy a boat someday. Maybe I’ll build a boat someday. In this shop, all things are possible.