I have become the master of doing things the hard way. I can take any simple task and stretch it out to a two weekend ordeal. I can make a bathroom renovation last longer than it takes to have a baby. I over-think solutions to make the greatest use of the smallest space, over-engineer things so they serve the greatest number of purposes possible. It’s an illness I have. Some kind of obsessive compulsive disorder. I don’t fight it, there’s no point in that. I just gotta run with it.

I have become the master of doing things the hard way. I can take any simple task and stretch it out to a two weekend ordeal. I can make a bathroom renovation last longer than it takes to have a baby. I over-think solutions to make the greatest use of the smallest space, over-engineer things so they serve the greatest number of purposes possible. It’s an illness I have. Some kind of obsessive compulsive disorder. I don’t fight it, there’s no point in that. I just gotta run with it.

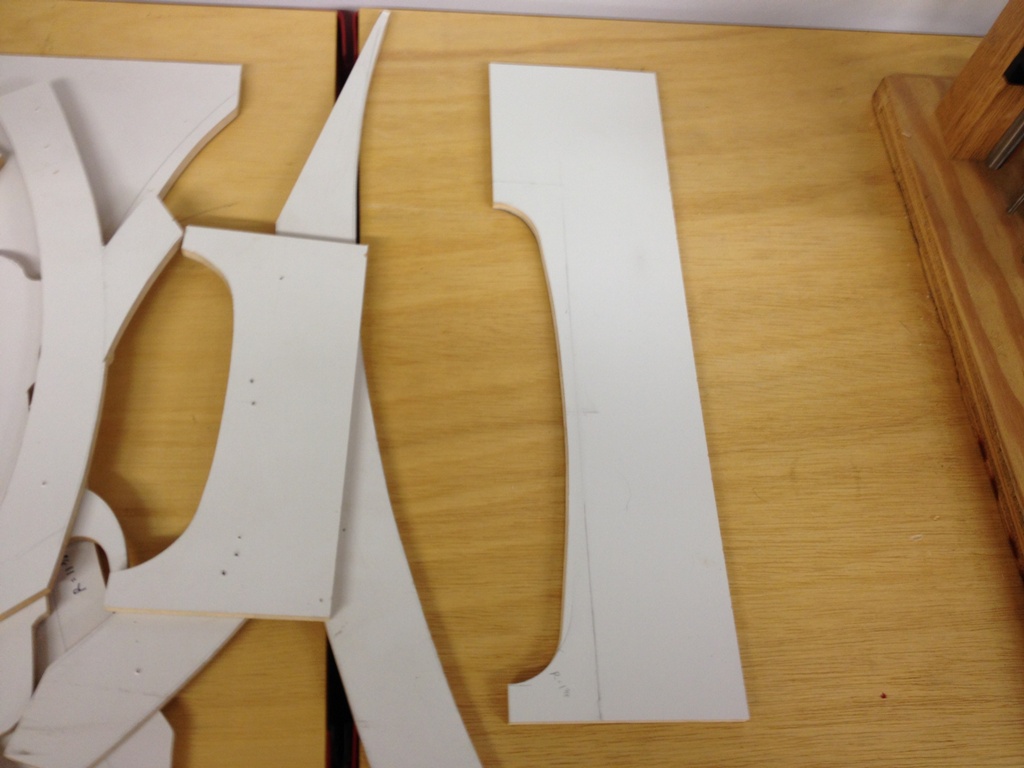

So, woodworkers and handymen alike usually have a small collection of 4′ x 8′ sheets of things. Everything comes in 4×8 now. Drywall, cement board, plywood, roofing material, everything. My collection of 4×8 was sitting in the corner of my garage like an oversized deck of cards, resting against a wall because there was nowhere else to put it. It was obstructing an electrical outlet, which offended me but I felt helpless to do anything about it. Until I learn wizardry and am able to just levitate them off the ground, there they will rest, held firm by gravity, forever obstructing a perfectly good 120 volt GFCI on the wall next to the punching bag.

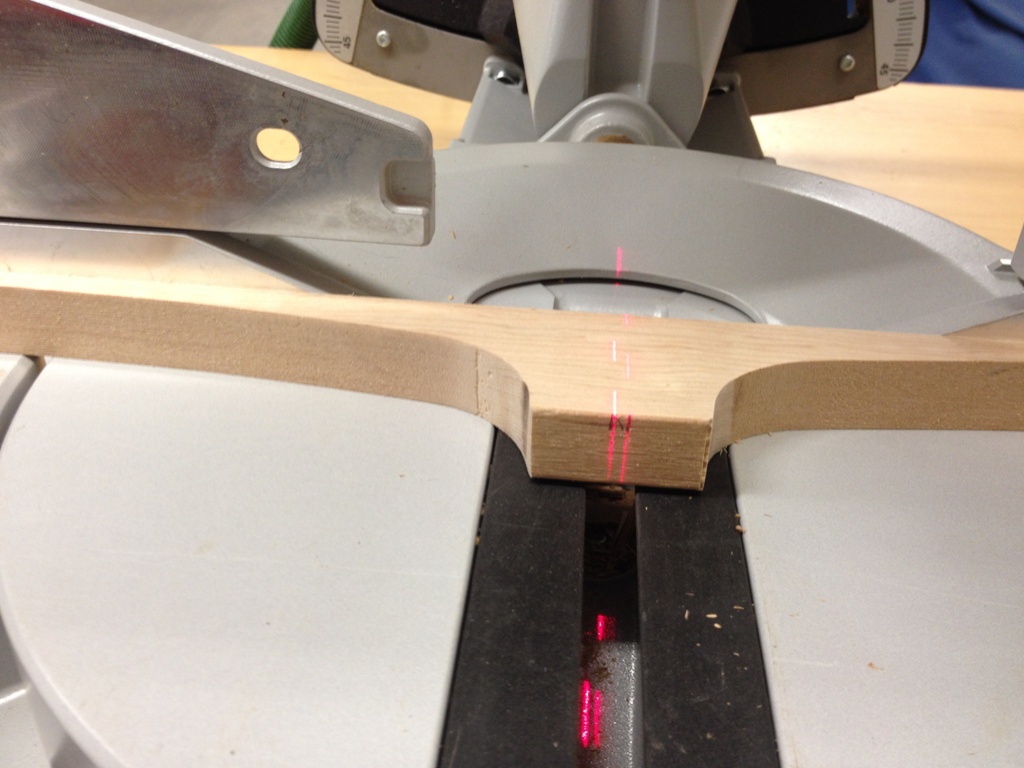

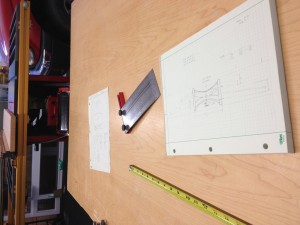

Well, no longer! How about I put them in the opposite corner of the garage, where there is more space! I don’t need to access these sheets frequently, so they can go sit in the corner and collect mouse poop. Then I can use the nearby corner for a dedicated cross cut countertop with my Festool radial arm saw. Woo hoo!

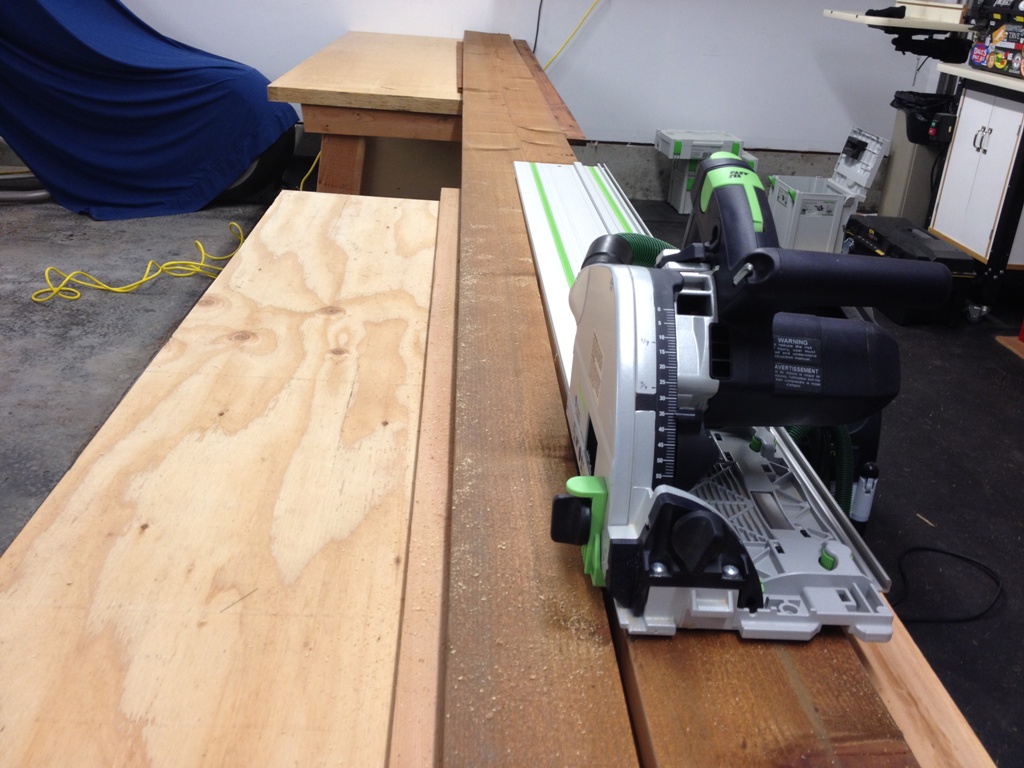

I started making a rack immediately. I could have just leaned them up against the wall but no, not me. I need to make a rack for them. Why? Because it’s harder to make a rack than it is to just lean them up against the wall! And I want them up off the floor because when we pull our wet vehicles in the garage floor gets wet and I don’t want my plywood getting wet. Ergo, a rack.

I started making a rack immediately. I could have just leaned them up against the wall but no, not me. I need to make a rack for them. Why? Because it’s harder to make a rack than it is to just lean them up against the wall! And I want them up off the floor because when we pull our wet vehicles in the garage floor gets wet and I don’t want my plywood getting wet. Ergo, a rack.

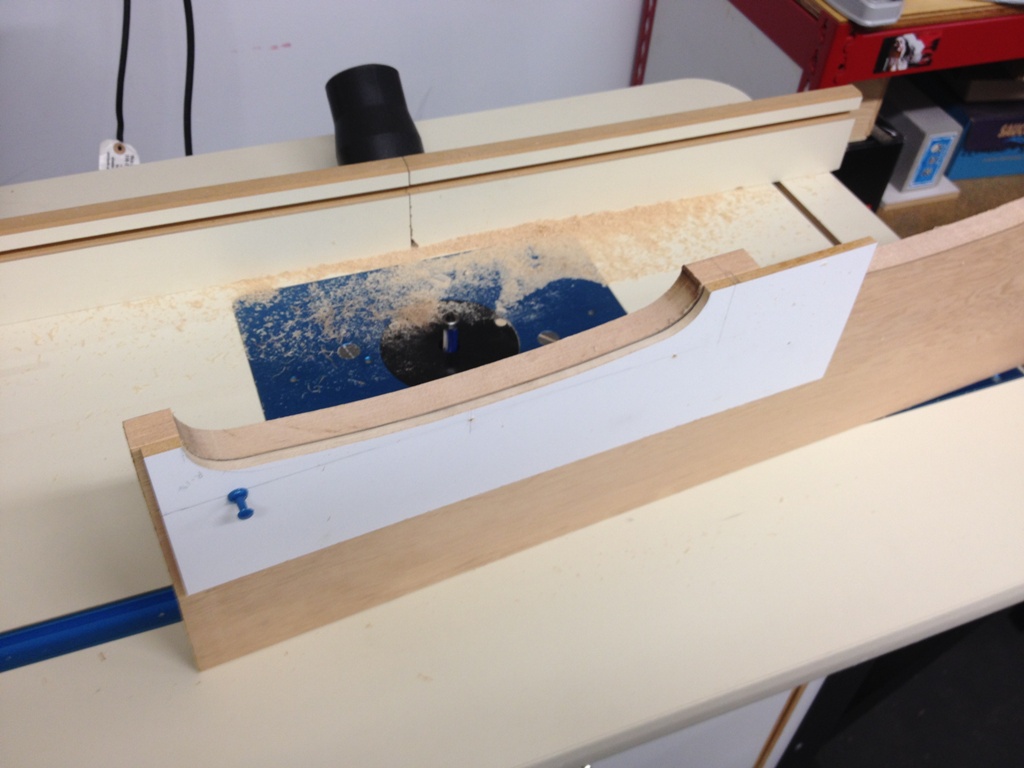

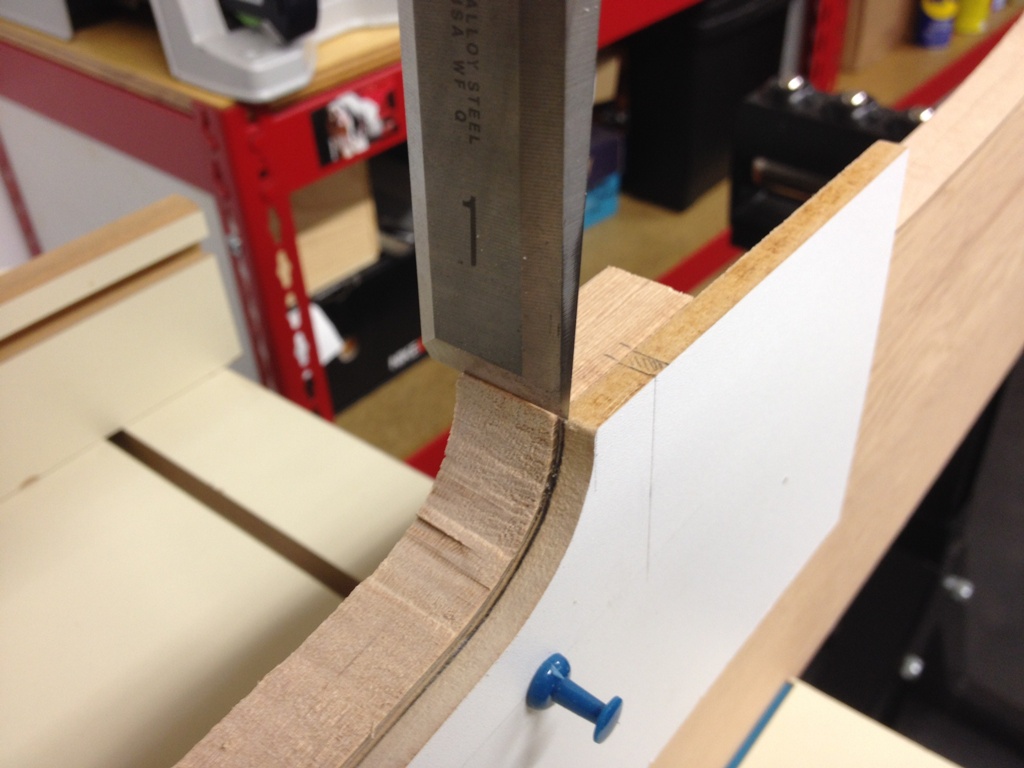

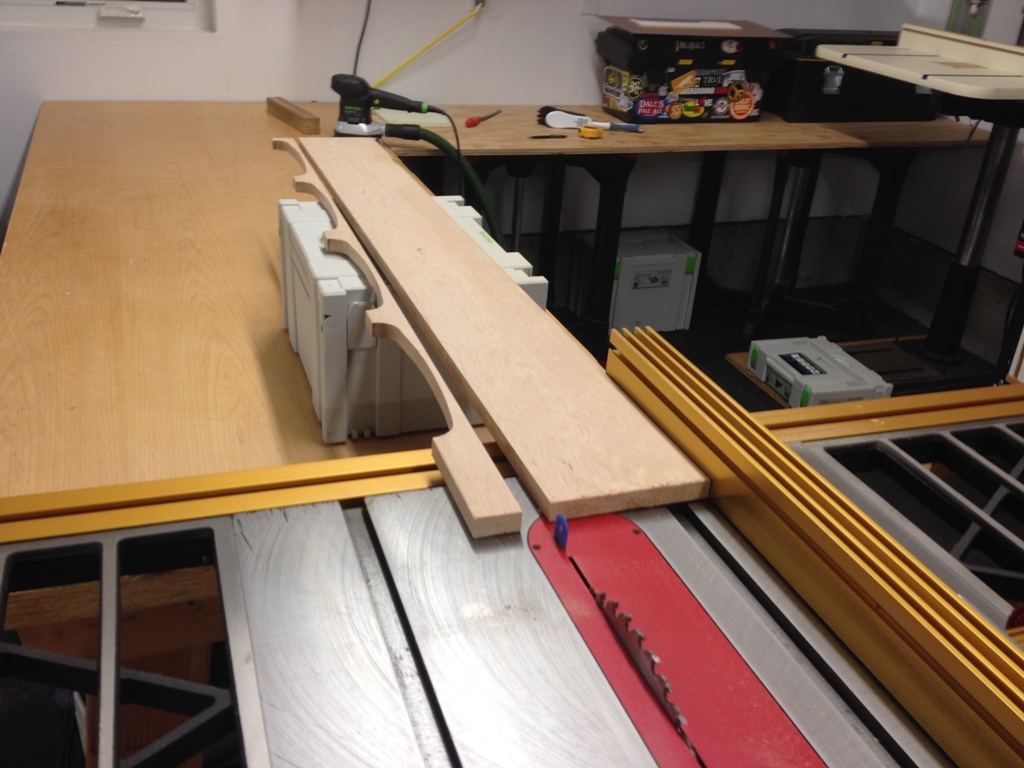

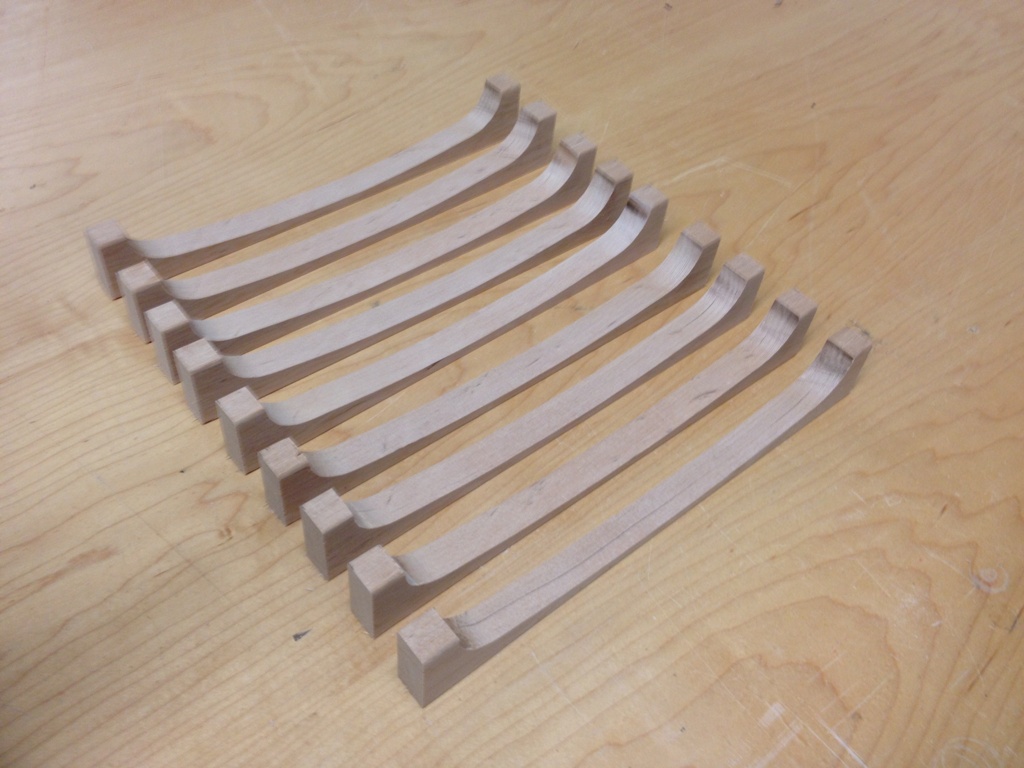

And the rack should be affixed to the wall. Oh yes. I can use 2×8 lumber, I got a ton of those things. They’re dirty and moldy but they’ll do. Obviously I have to taper them so they lean against the wall at a slight angle, so the sheets can rest without falling over. Tapering them requires careful measurement and cutting but what the heck, this is a YOLO moment if there ever was one. Oh, and hey, I can sand them and stain them and coat them with layers of polyurethane too! (Yes, this insane thought seriously went through my head. I even sanded a few pieces before I stopped to realize how stupid that was.)

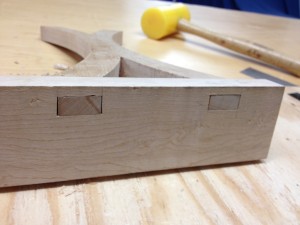

The rack will have double joists spaced about 20 inches apart, as can be seen above. It will easily support about 42,700 pounds of 4×8 sheets, which is some 41,700 pounds more than I’ll ever have.

Here the rack is almost fully assembled. I decided to rest them vertically against the wall to save space. I have nine foot ceiling height in the garage so may as well take advantage of that. And that way, I can access that electrical outlet pretty easily. Those things are important. Will the garage door rail get in the way when I’m trying to put away and retrieve my 4×8 sheets? Of course it will! I did that on purpose, so I can do things the hard way.

Here the rack is almost fully assembled. I decided to rest them vertically against the wall to save space. I have nine foot ceiling height in the garage so may as well take advantage of that. And that way, I can access that electrical outlet pretty easily. Those things are important. Will the garage door rail get in the way when I’m trying to put away and retrieve my 4×8 sheets? Of course it will! I did that on purpose, so I can do things the hard way.

And here’s the rack all filled up. My garage abhors a vacuum. All that joinery and engineering can’t even be seen behind the drywall and plywood and scraps of cardboard that I’m keeping because I just know they’ll come in handy someday.

And there it will sit, until the day comes I get a better idea of where and how to store 4 x 8 sheets. Tomorrow? Ten years from now? No one knows.