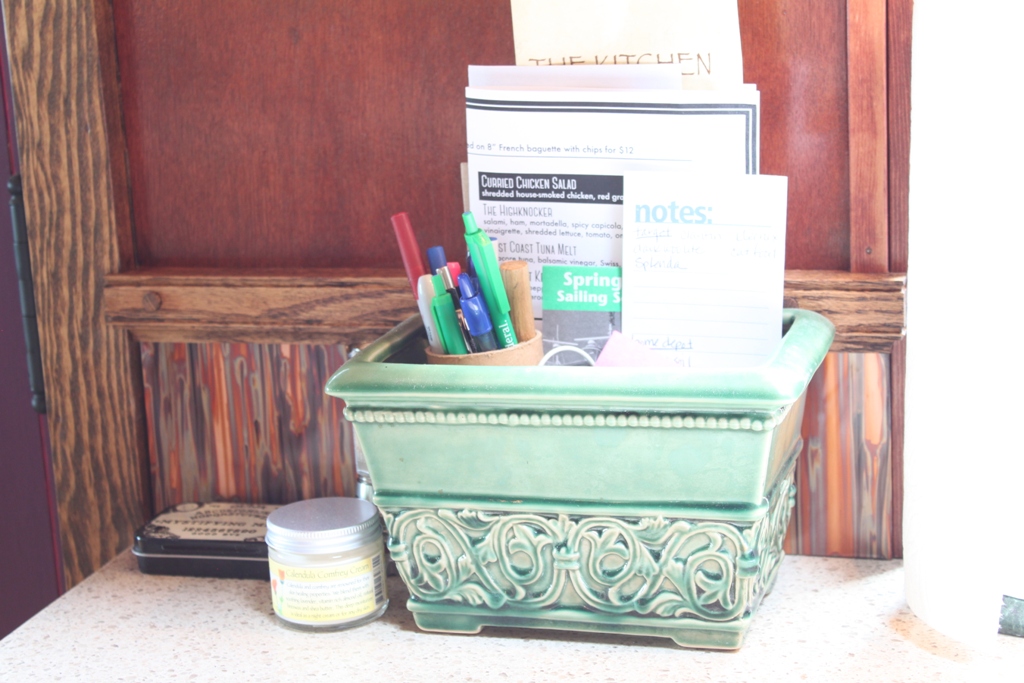

Let’s take a moment to let the above picture sink in. The lovely paneling. The yellow linoleum floor. The pencil sharpener. You see how those cabinets look like they lean in a little? That’s not a trick of the camera, they actually did lean in a little bit.

There isn’t much in the way of fast food on this island, so we cook a lot. Getting this kitchen fixed up was a huge priority, and it was also a huge undertaking.

Here we go, all finished.

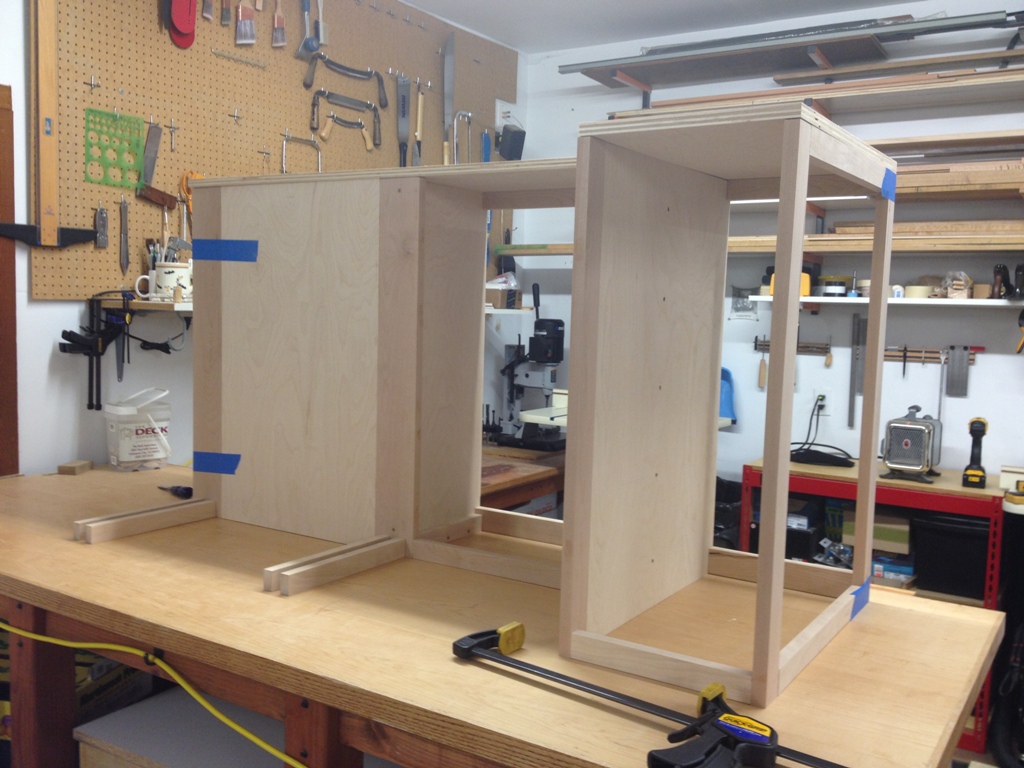

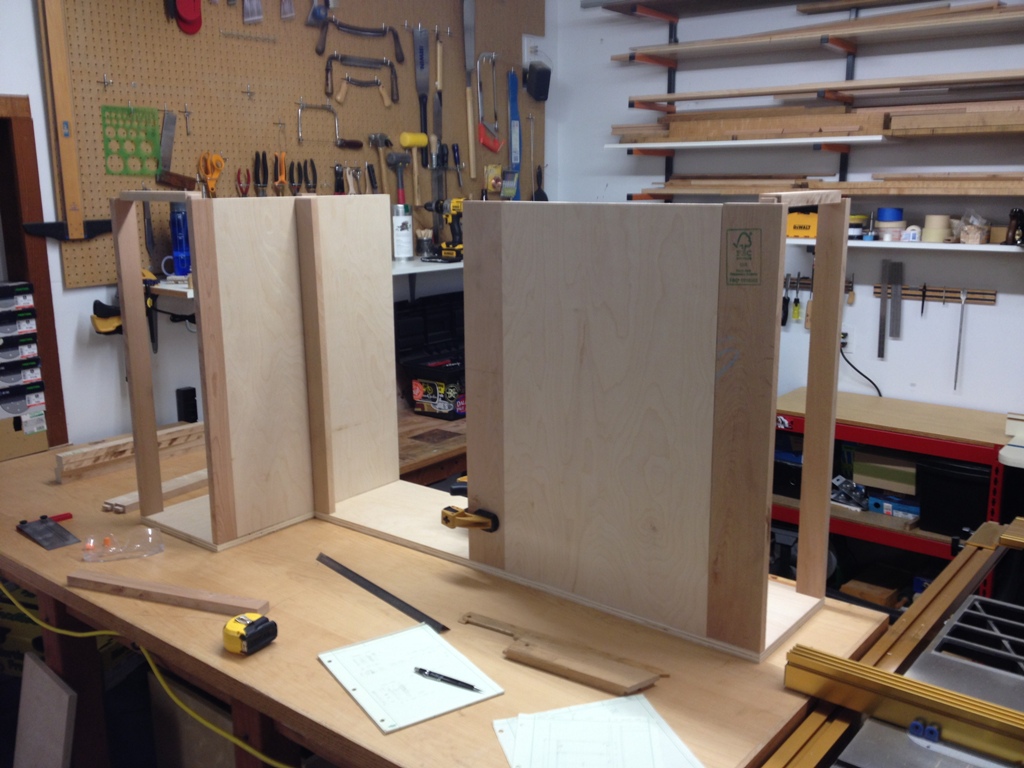

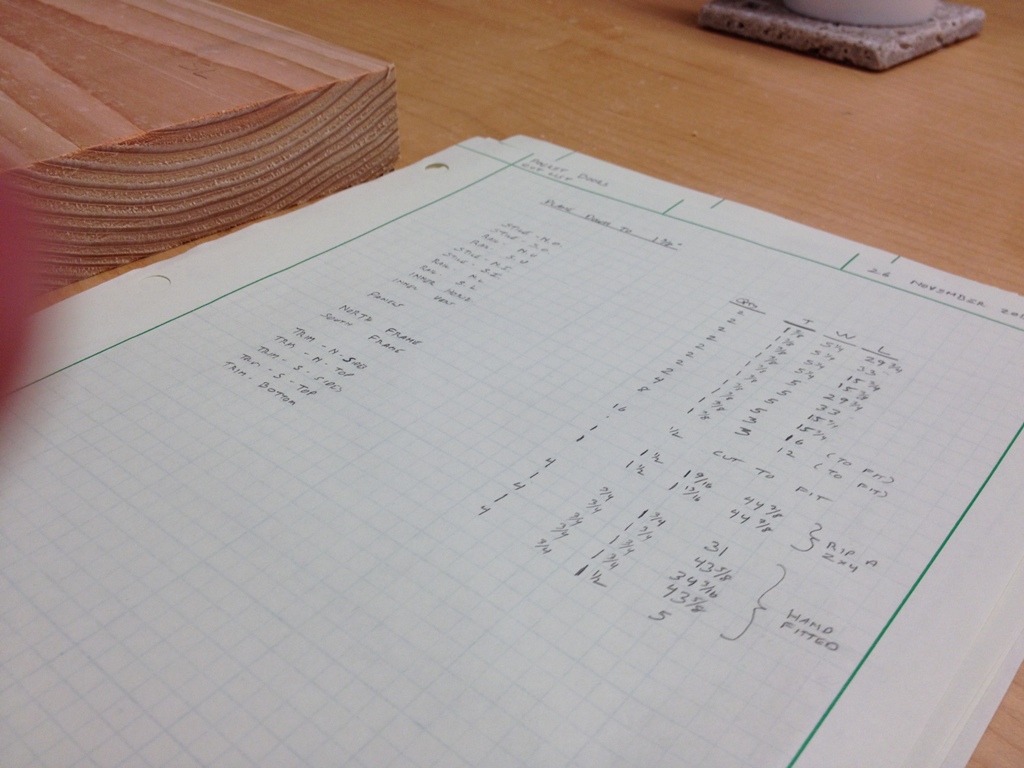

Part of the challenge was having to use our kitchen while it was being worked on. As much as I wanted to gut the whole thing down to the studs and start fresh, that would have left us without a working kitchen for days at the very least, if not weeks. So, I ended up doing it the hard way, just a little bit at a time, as budgeting and timing permitted.

I like how the woodwork came out. The half wall cap looks really nice.

Definitely an improvement, anyway.

This used to be a wall covered with big boxy cabinets. And while the extra storage space was nice, it just made the kitchen look like the inside of a matchbox and, even worse, obstructed the view of the hockey game. That’s unacceptable in our house. We go to great lengths to be able to see hockey.

You can even see hockey as you walk in the side door.

The copper backsplash is one of my favorite additions to the kitchen. It adds some really beautiful color.

Lots of deep, island-y colors going on in our kitchen.

This is a pretty hard working spot, sometimes cooking two or three meals a day here. The wall mounted spice racks are pretty tight; I had a hard time determining what my twelve favorite spices are, and we had to fit in a thirteenth in there anyway.

Here’s our super clever trash can solution. It’s not as cool as it looks. In fact, it’s kind of a pain in the ass. But it works, and it keeps the trash can out of sight when you’re not using it, or right next to you when you need it.

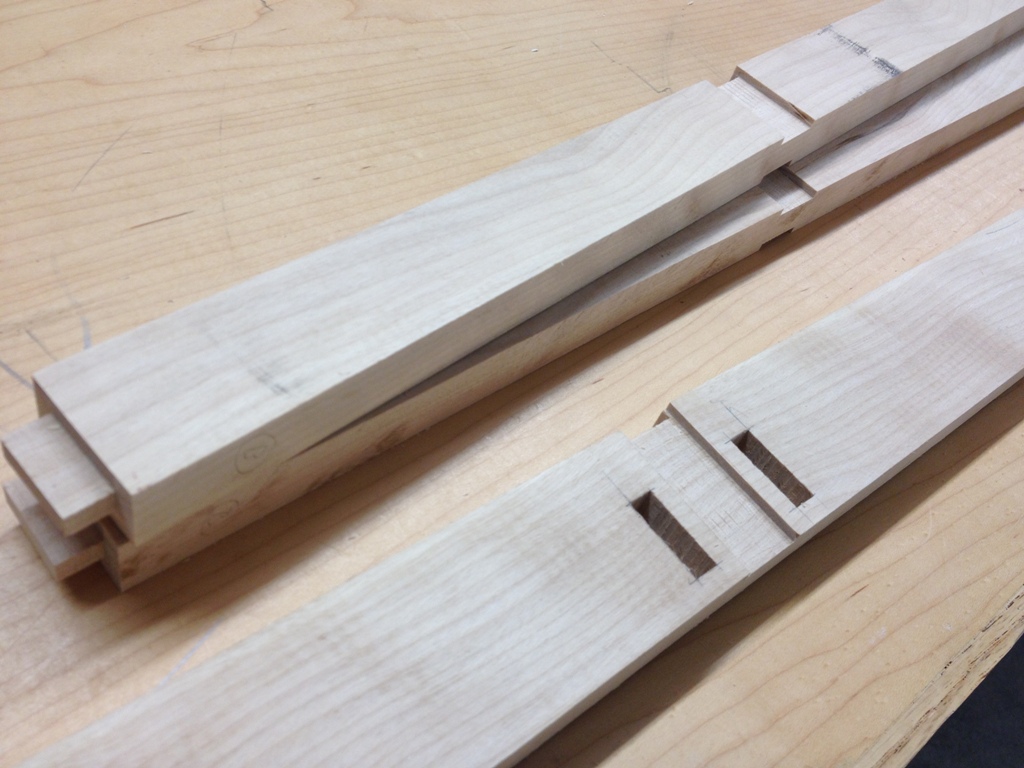

Here’s a close up of the work I had to do to get the sink to fit. Those doors used to be inset, but I had to make them flush with the front surface. For the new gap in the middle, I just put some of that copper backsplash. Looks great.

The old countertops used to go all the way to the window, but we couldn’t do it that way this time because (1) the new countertops are thicker and the window would not be able to open or close, and (2) eventually that window is going to get replaced, and I can’t install a new window on top of the new contertops. So I just put a piece of wood back there. Quartersawn white oak, so it’s pretty stable, and it’s got a few coats of poly on it and some caulk in the joints but it’s otherwise floating and can be removed. I’m so clever, huh?

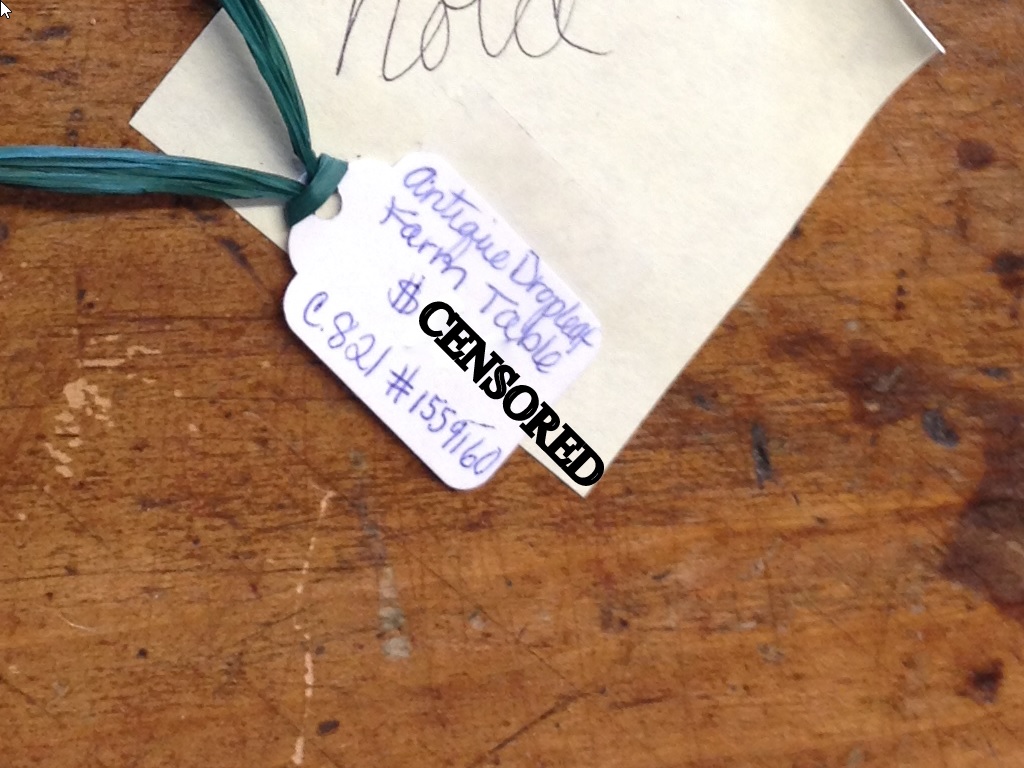

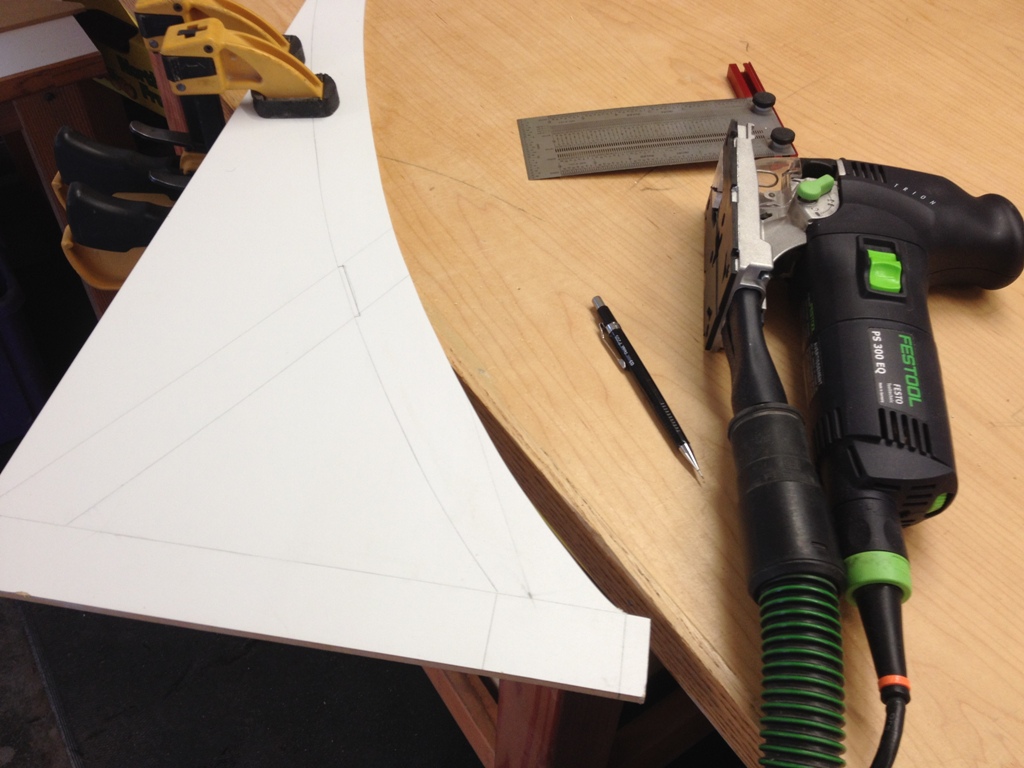

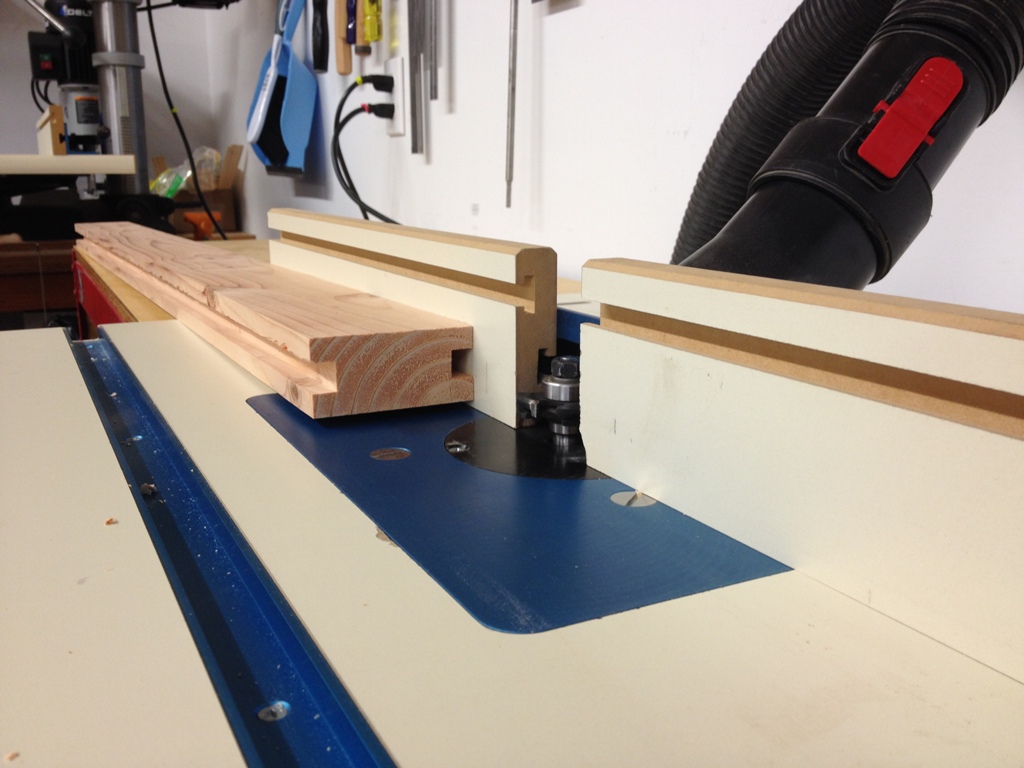

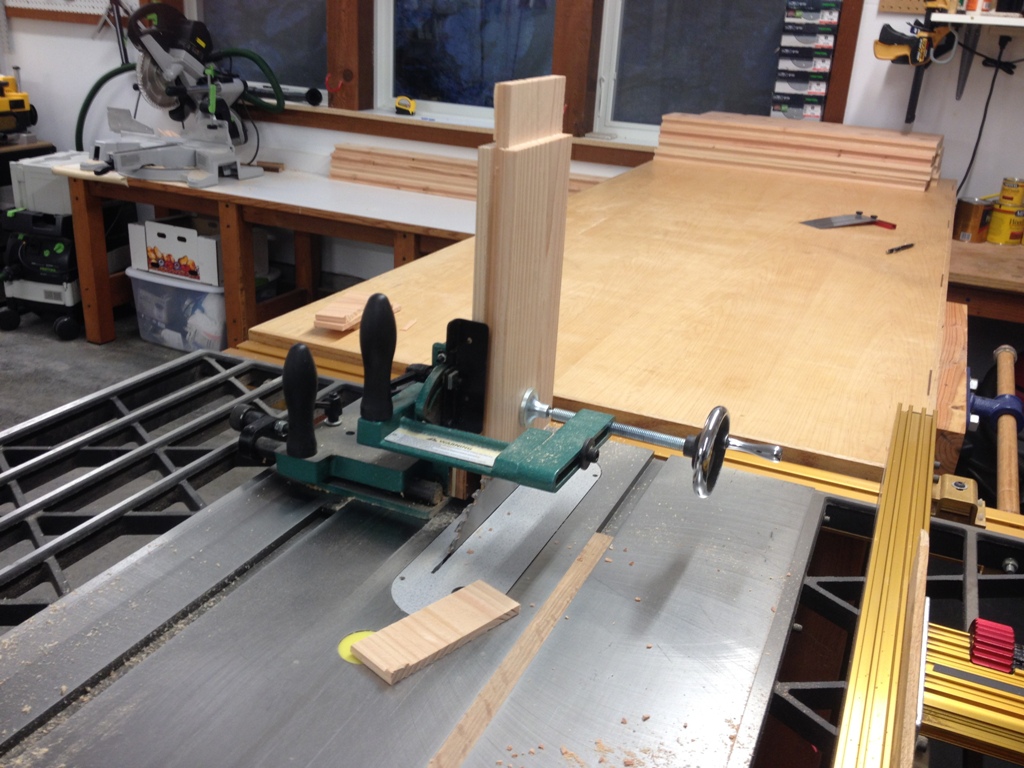

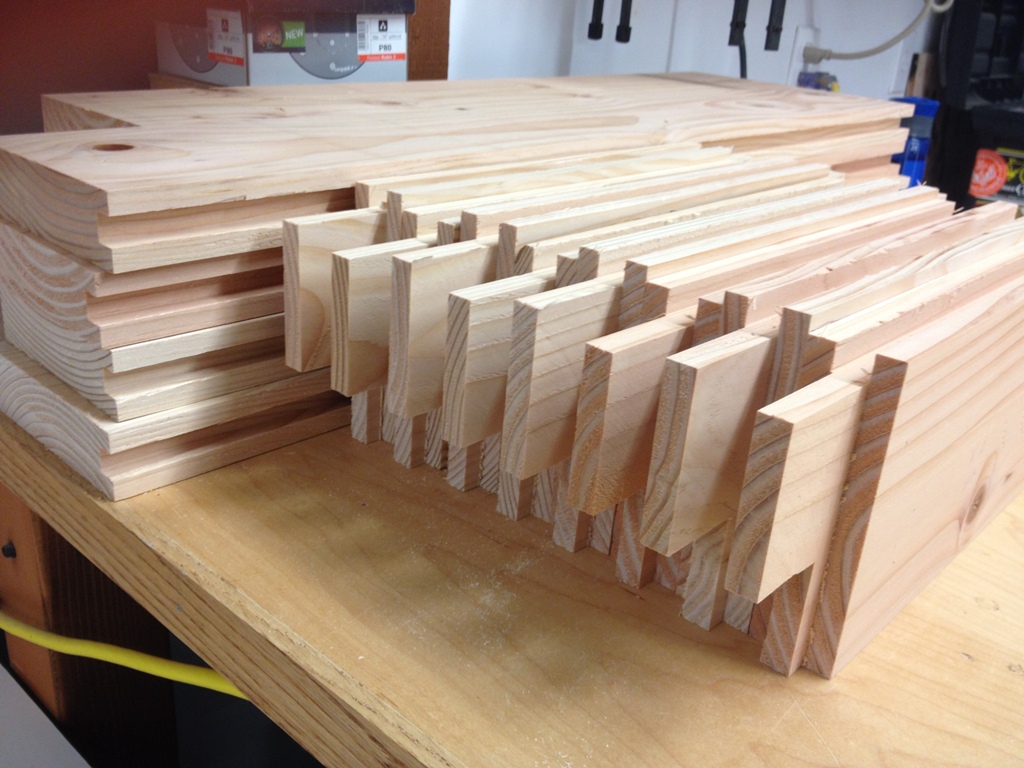

That banded trim piece up there was one meticulously cut piece of wood. It had to be carefully fitted to attach, all hand cut.

You could fill this sink up with water, put toy boats in it and have little pirate ship fights in there. The new sink is just HUGE! I put dirty dishes in it and I forget them because I never see them.

And Inky still has her catwalk up there, so she can get from the top of one cabinet to the other.

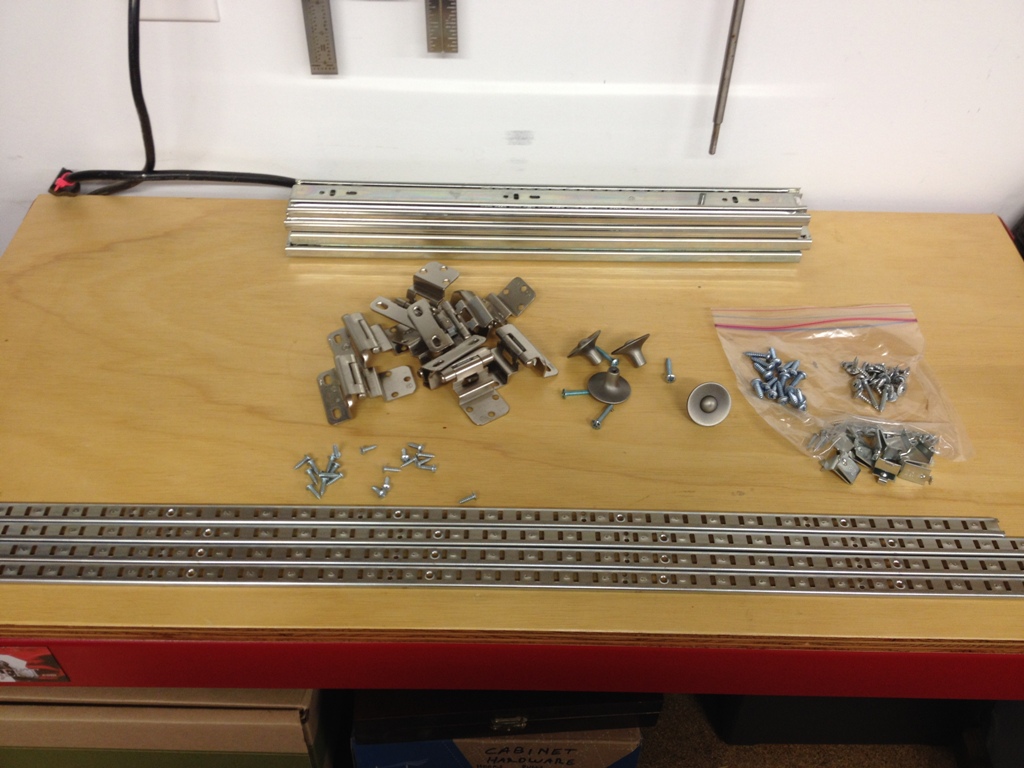

Still not my favorite cabinets, but with new hardware and a contrasting stain color they turned out alright.

It’s definitely come a long way.