When we left off last time, the loft had become a bit of a war zone. Paneling had been torn off, framing had been nailed into place, drywall had been screwn on and joint compound was drying in the seams. In my head, these things take like an hour, but in reality it takes weeks.

I called this the Corner of Horror.

Yuck. When you’ve lived with this paneling for a few years, there’s a part of you that doesn’t even see it anymore. It’s like a disease without any symptoms, slowly killing you inside and you don’t even know why.

That white stuff is frass. It’s what carpenter ants leave behind when they tunnel through wood. It’s ant poop.

These triangles were tricky cuts. Trickier still carrying the cut pieces up the stairs without damaging anything. And there really weren’t any good beams to screw it into behind it, I had to get a little creative sticking these to the framing.

I really only had one drywall seam on this install. Most pieces were small enough I could just cut them out of a single sheet. That bottom piece on the left hand side had four cut outs for boxes: one electrical outlet, one phone jack, one cable and internet box, and a box for the rear speaker hookups. I must have measured everything out six times before I cut that piece. If I screwed it up, I wouldn’t have enough drywall to finish.

Finally got some paint on the walls. I had the trim all cut and finished before I even started painting, so the trim install went very quickly.

I even finished the inside of the closet. It looks like there’s a light inside but that’s just my work lamp. It’s an eight square foot room with a low ceiling. I’ve seen refrigerators bigger than that. It doesn’t get its own light.

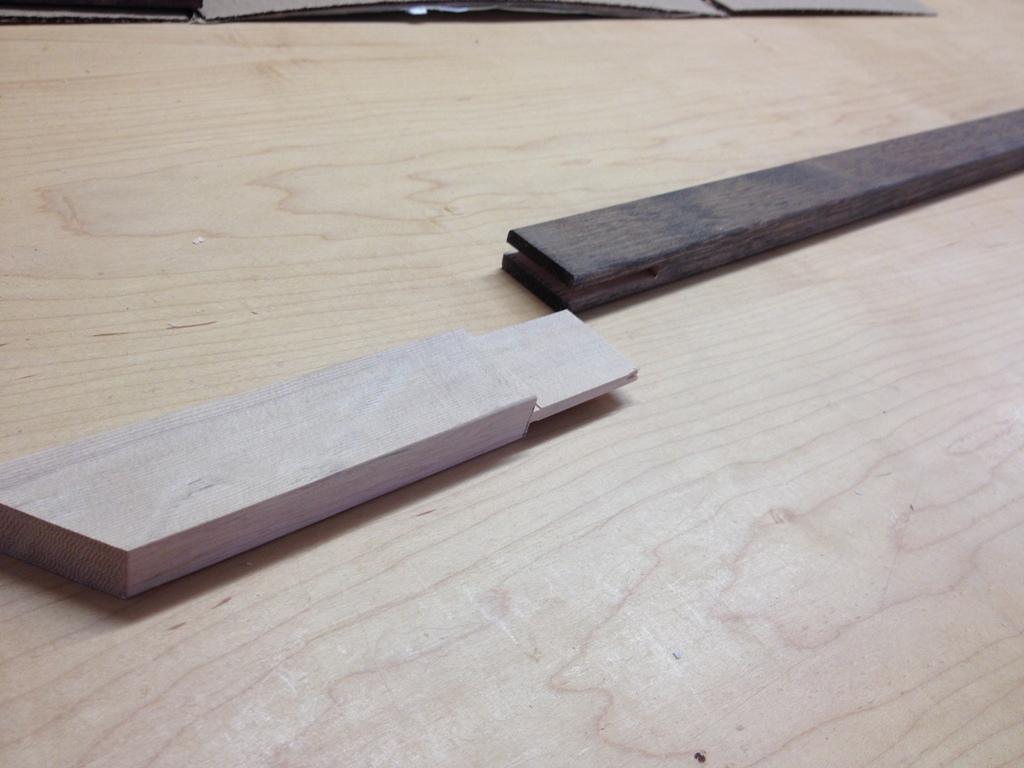

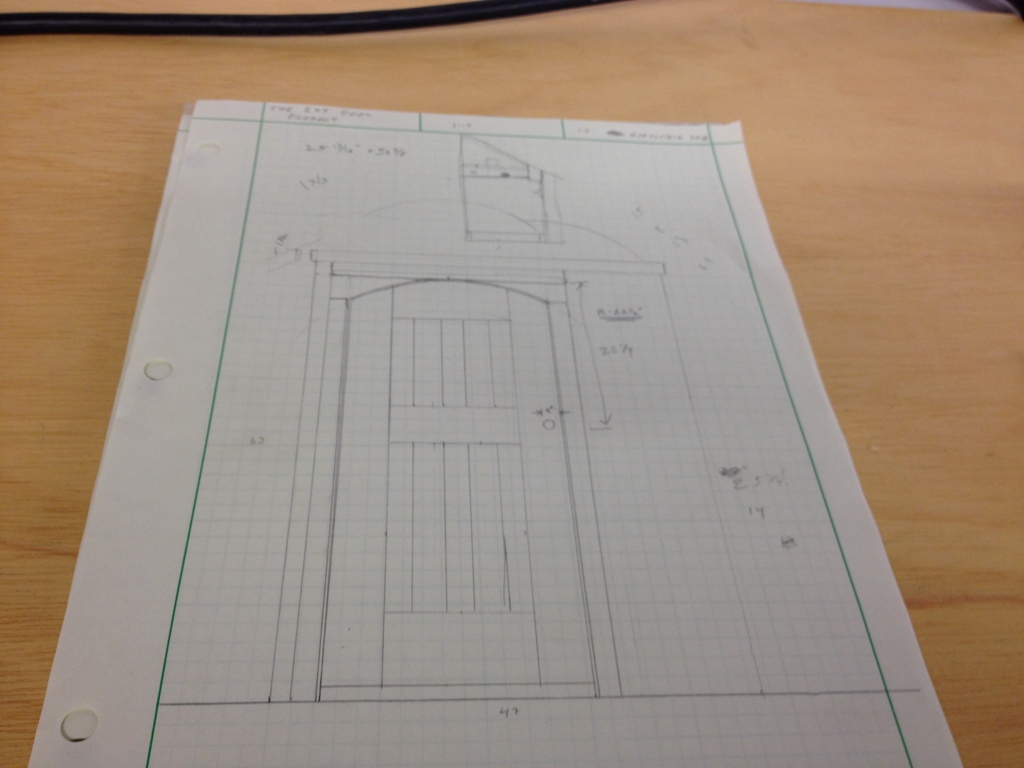

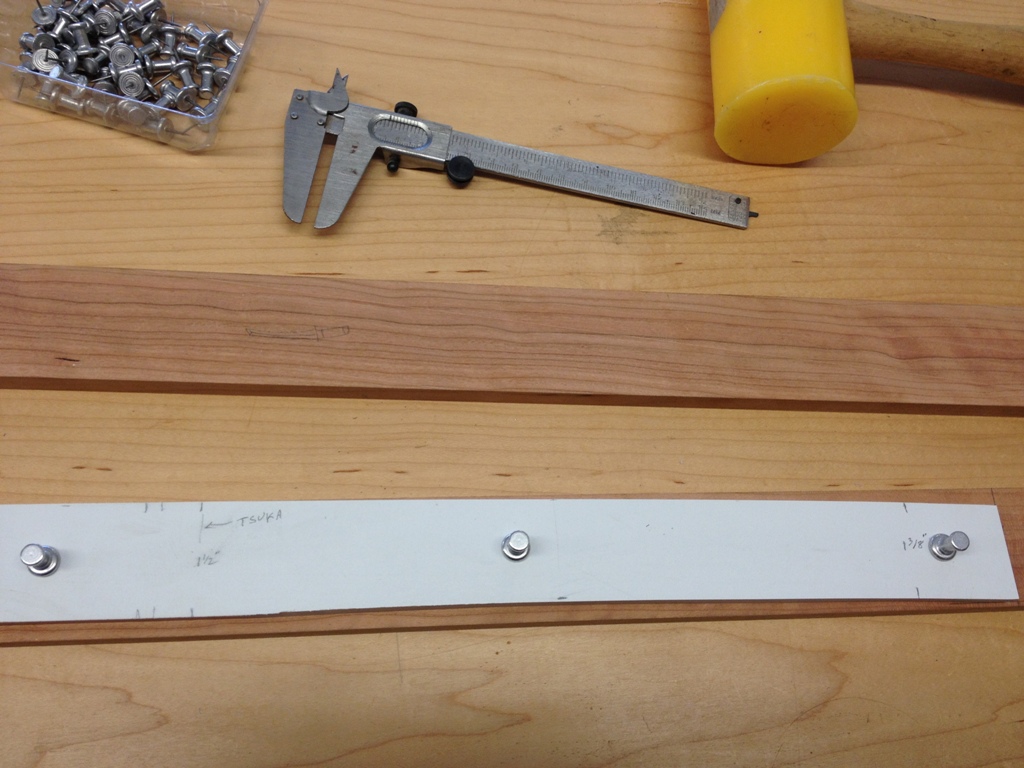

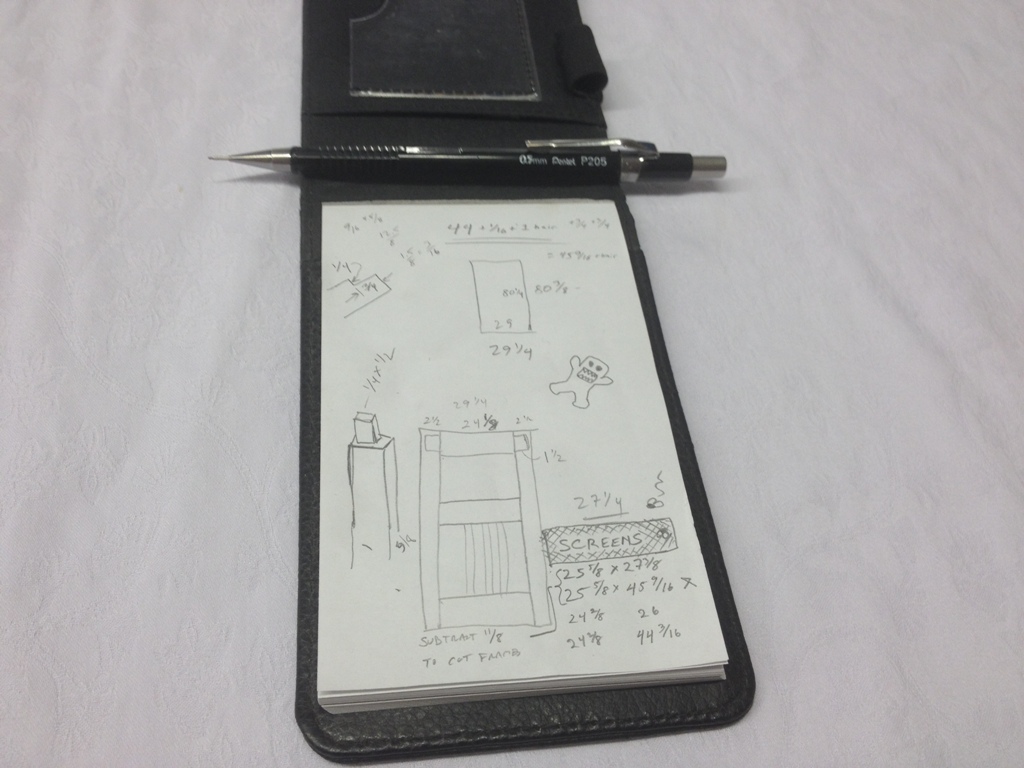

A lot of the big tasks are now finished, but there are still some major projects ahead. I need to make windowsills for both windows, I have a special way that I’ve done to other windowsills in the house so it’s not as simple as nailing a board down and pouring half a bottle of shellac over it. Which is how the current windowsills were done.

And then there’s flooring. The floor sags pretty badly in the middle and it’s a little spongy, so I have some structural work to do before I even put down a finished floor. Currently, I’m walking on plywood panels that have been here since Nixon was president. The good news is if it hasn’t caved in by now it probably won’t, but I’d like to at least try to shore it up a bit.

I finally have the desk fit into a little nook so that it doesn’t block any windows. I not only have a nice view, but I get some natural light. The green sleeping pad over there is for Inky, she loves it and sleeps there daily.

With the desk in a nook, it’s really opened up some space in the loft. It’s not a big room at all and the A frame limits moving around very much. In small houses it’s really important to make the best use of your space. Or, be very small. In fact, I bet this house is considered fairly large by cats, squirrels and mice.

The Hobbit Door is at last in place. I love it. The whole thing cost about $60 and almost half of that was the hinges.

There’s a bit of an unfinished corner up there. And speaking of doors, I need to make some pocket doors for those storage area. And see where that cheap bookshelf is? I’m going to put a nice built-in bookshelf in its place, a bit bigger and with some better storage spaces.

And see that gap between the beam and the ceiling timbers? The ceiling isn’t straight. My guess is when they made the dormer up here they didn’t support the roof correctly. They had to cut a load bearing beam to make this dormer so maybe that was their problem. Anyway, it’s now my problem and I need to find a way to either fix that gap or cover it up. There’s really nowhere to put the load of that roof anymore, so I’ll probably just cover it up.

Looks great from downstairs too. Well, it looks better than it did. And now the handrail and balusters look really awful so I guess they’ll have to go soon. Very soon.